If the actual information at the lifting site does not tally with the lifting plan, you should stop the operation until the plan has been updated and re-approved. You should never deviate or vary from the approved lifting plan. The load to be lifted must have certified lifting points or be. The lift is not in a restricted, difficult or sensitive area. The lift is from a dedicated structure (pad eyes, runway. The lift is carried out using a crane’s main hoist. Sketch of the lifting zone (showing position of lifting equipment, crew and load) and The lift involves the use of basic hoisting equipment. Requirements to erect or dismantle lifting equipment (if any). Lifting crew (including their roles and competencies).

Your lifting plan should include, but not limited to, the following elements: Note: Applies to Cranes, Derricks, Hoists and Power-Operated equipment that can be used to hoist, lower and/or horizontally move a suspended load (includes excavators, forklifts, Rough Terrain. load capacity chart, range diagram, rigging method)įor complex lifts, additional engineering design efforts are necessary to ensure that the lifting operation is conducted safely.

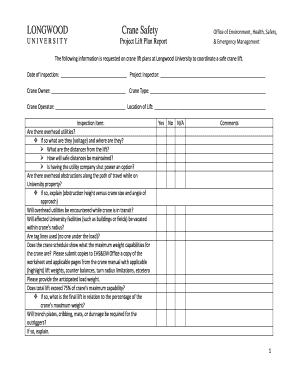

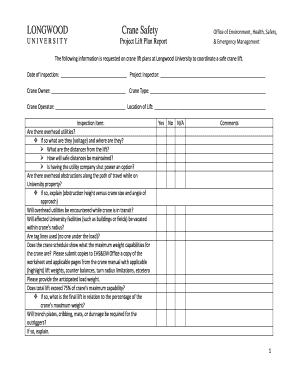

Safe work procedure or method statement. Lifting plan supported by a risk assessment (RA). Discus safety issues including environment, hazards, use of personnel protective equipment (PPE), first aid and medical support and emergency procedures. Provide site-specific lift plan that complies with OSHA Standard Cranes and Derricks 1926 subpart CC to Construction Project Manager (CM).

For example, a lifting plan would ensure that the crane is safely deployed and operated, and the lifting crew are clear about their roles and responsibilities.īefore you start any lifting operation, you must prepare the following: Toolbox Talk Outline Discuss the current task to be done. A lifting plan provides a systematic approach towards planning a lift and ensures that the lifting operation is properly managed.

0 kommentar(er)

0 kommentar(er)